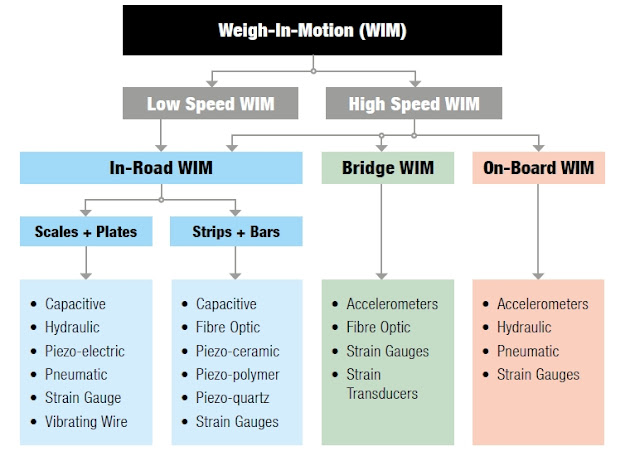

Different types of vehicle weighing Independent of the sensing technology used, there are several different ways to measure the gross vehicle weight, axle group loads and axle loads of a vehicle. In general, a complete WIM system includes: 1. A set of weighing sensors, either mounted in the pavement (In-road sensors), or attached to a bridge (B-WIM). For on-board WIM, the sensors are installed on the vehicle. Additional sensors are mostly used to measure vehicle speed, length, wheel transverse location, etc. Road sensors can be scales, plates, strips or bars mounted inside the pavement, and sometimes mats attached to the pavement surface. Strain transducers or strain gauges are most commonly used for Bridge WIM installations. Strain gauges, load cells, pressure transducers, etc. are used for on-board weighing. 2. A road side unit – or central vehicle unit - containing all the electronics including a data acquisition tool, data processing unit with software for weight calculation, (se