Key Design of Direct Enforcement Inspection Stations for Road Overload Control

1. Introduction

Illegal overloading and overloading of trucks not

only destroys highways and bridge facilities, but also easily causes road

traffic accidents and endangers the safety of people's lives and property.

According to statistics, more than 80% of road traffic accidents caused by

trucks are related to oversized and overloaded transportation.

The traditional overrun and overloaded transportation checkpoint mode has

low law enforcement efficiency, which is easy to cause the phenomenon of

overrun vehicle omission, and the direct enforcement detection point control

mode relies on the dynamic automatic weighing and detection system to

automatically detect, identify and screen the passing vehicles around the

clock, so as to achieve accurate and efficient control of overrun and overloaded

vehicles. In order to strengthen the governance of overloaded transportation

behavior, ensure the safety of highway facilities and people's lives and

property, the direct enforcement system of road overrun has gradually been

fully promoted and applied in the highway, and the overrun control of highway

has achieved remarkable results, and the control of highway overrun rate has

been controlled within 0.5%, and the illegal overrun and overload of ordinary

highways have also been effectively curbed.

2. The framework of the direct enforcement system

2.1. Framework and functions of the governance system

The direct

enforcement mode refers to the automatic acquisition of relevant data such as

the weight of passing vehicles through high-speed and accurate dynamic weighing

equipment, so as to determine whether the freight vehicles are overloaded and

transported, and rely on scientific and technological means to obtain evidence,

and notify and deal with them afterwards.

The national network management information system is organized and

constructed by the Ministry of Transport, and the provincial system data is

connected and shared, providing support for the inter-ministerial and

inter-provincial business coordination, and effectively supervising the

national governance and super-governance work; The provincial-level project

shall be organized and constructed by the provincial (autonomous region,

municipal) transportation department to realize the functions of business management

and service within the jurisdiction, support the provincial, municipal and

county levels to carry out the work of inspection, and connect with the

ministry-level system.

Taking Zhejiang as an example, the province's networked

governance system adopts a four-layer structure and three-level management from

top to bottom, which are as follows:

1) Provincial governance platform

It plays the role of six major platforms in the

province's networked governance system, namely: basic data center platform,

data exchange platform, administrative punishment platform, one-time illegal

auxiliary judgment platform, assessment and evaluation platform and statistical

analysis and display platform. Connect with the provincial government service

network to obtain the matter database, discretionary database, and law

enforcement personnel database, and report administrative punishment handling information

in real time; Docking with the traffic police system to obtain freight vehicle

information and driver information, copy illegal overrun transportation

information; Docking with the transportation management system to obtain

information on transportation enterprises, freight vehicles, etc., and copying

illegal overrun transportation information; Unified document template and basic

information and blacklist/license management of the governance station; Realize

the auxiliary ruling of one penalty for one trip of oversized transportation;

Assess and evaluate the operation of the province's monitoring stations and the

operation of the super-control business; Through the statistics and analysis of

data, the province's policy of governance and super-governance is evaluated,

and quantitative support is provided for the introduction of the policy;

Provide relevant legal and regulatory support for the work of governance at all

levels, and establish a business database at the provincial, municipal, and

county levels.

2) Prefecture-level governance super module

Responsible for the comprehensive

management of basic business information within the jurisdiction, statistical

analysis of overrun information, law enforcement inspection of the local city,

administrative reconsideration of the case, business deployment, inspection and

evaluation of the local city.

3) District and county governance super module

Receive and store the data of

various overrun detection sites and facilities in the jurisdiction (including

all kinds of overrun detection data, pictures and videos).

Collect/review/confirm the illegal overrun data in the area, file archiving,

and relevant statistics, analysis and display in the district and county.

4) Direct enforcement inspection stations

Through the dynamic weighing and capture forensics

equipment set up on the road, the weight, license plate and other relevant

information of the passing truck are obtained.

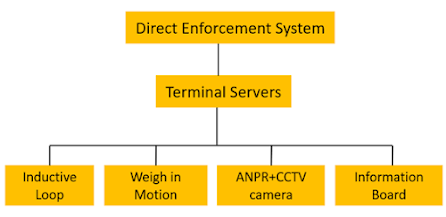

2.2. Composition and function of direct enforcement system

The field equipment of the direct

enforcement system (see Figure 1) mainly includes automatic weighing and

detection equipment, vehicle capture and identification equipment, illegal

behavior notification facilities, video surveillance equipment, etc.

1) Weighing equipment: including

weighing sensors, weighing controllers (industrial computers), car

distributors, etc., should be verified by relevant qualified measurement

institutions, and the weighing results can be used as the basis for punishment.

2) High-definition recognition and

capture equipment: used to collect images of vehicles, including license

plates, body conditions, license plate numbers and colors that can identify

vehicles.

3) Video surveillance equipment:

the use of video surveillance equipment to obtain the process of automatic

weighing detection equipment for trucks, and the monitoring information

obtained by video surveillance equipment can be used as evidence.

4) Information release equipment:

through the variable information board, the vehicle that has been tested and

overrun can be issued in real time to overrun the notice, and guide the truck

driver to the nearest unloading site for unloading.

Figure 1. Diagram of the composition of the direct enforcement system

3. Design of direct enforcement detection

points

In order to

improve the effectiveness of overkill, direct enforcement inspection stations

should be selected in accordance with the principle of "overall planning

and unified layout", and priority should be given to roads with the

following characteristics:

1) Trucks are seriously overrun or trucks must pass

through the road;

2) roads connected to key protected bridges;

3) Provincial borders, municipal boundaries and

other administrative areas junction roads;

4) Rural roads that are easy for vehicles to detour.

Dynamic truck scale is an automatic weighing instrument used to measure the

longitudinal mass (gross weight), axle load, and axle group load when the

vehicle passes, and it mainly has load

The device, the data processing part and the display instrument are

composed, wherein the data processing part is usually designed in the form of a

control cabinet. According to the different carriers, dynamic truck scales can

be divided into vehicle type, axle load type, double platform type, axle group

type, multi-arrangement combination type, and flat plate type can also be

regarded as the category of axle group type. The working principle of the

carrier is to measure the electrical signal when the carrier bears the tire

load, and then convert it into the mass of the vehicle through amplification

and signal processing, which can be divided into two categories: strain gauge

type and quartz crystal type.

Under the condition of meeting the

requirements of detection accuracy, the appropriate dynamic truck scale should

be selected according to the road conditions, and the use of new technology

weighing equipment with high precision, low cost and in line with standards

should be encouraged, and the trucks that can be queued up and passed through

the non-stop weighing detection area can be accurately separated.

3.2.2. Deployment of outfield equipment

Figure 2 is a typical layout diagram of direct enforcement stations, and

Table 1 is the functional requirements of the main equipment. When the direct

enforcement detection point is set on a single pavement road, a dynamic truck

scale should be set on the entire road cross-section, and if the entire

cross-section cannot be set up due to conditions, isolation facilities such as

wrong-way driving and riding should be added to avoid vehicles evading

weighing.

Figure 2. Typical diagram of the direct enforcement station

Table 1.Key Device Functional Requirements

|

|

The name of

the device |

Key feature

requirements: |

|

1 |

Dynamic

truck scales |

It can automatically detect the time, number of axles,

speed, single axle axle load, total weight of vehicle and cargo, wheelbase

and other information of the vehicle; It can accurately separate the queuing

mode through the freight vehicle; It can deal with the abnormal driving state

of freight vehicles such as lane change and speed breaking; It can transmit

the front-end truck overrun information to the management system in real

time; It can meet the uninterrupted all-weather continuous work in the unattended

state; It should have a fault self-test function |

|

2 |

License plate recognition and capture equipment |

should be equipped with a fill light or flashing light;

It can clearly capture the license plate number, has environmental protection

configuration, and it is recommended to use a three-in-one fill light to

avoid light pollution; Ability to capture images of freight vehicle number

plates in full-frame JPG format; It should be able to capture 1

high-definition picture of the front, and according to the picture

information, it should be able to clearly distinguish the license plate area

of the freight vehicle, the front and cab features, and the color of the

front of the car; The vehicle identification and capture equipment should be

able to capture the image of the vehicle passing through the non-stop

weighing detection area from multiple angles from the side and tail, and

should be able to clearly distinguish the number of axles of the freight

vehicle, the color of the body, and the basic situation of the transported

goods according to the image information; Vehicle identification and capture

equipment should have fault self-inspection function; The abnormal event

capture device supports the detection function of abnormal vehicle crossing

and compaction line. |

|

3 |

Video

surveillance equipment |

Forensic images

should be at least 2 million pixels and should be tamper-proof. |

|

4 |

Information

Publishing Equipment |

It should be able to release the vehicle overrun

detection information to the driver of the overrun vehicle in real time, and

it should be able to realize text alternation, scrolling and other display

methods. |

When a vehicle is detected to be suspected of being

overloaded, the license plate will be displayed via a variable information

board and the vehicle will be directed to a nearby overloaded transport

checkpoint for processing. The setting distance between the information board

and the dynamic truck scale should meet the requirements of vehicle vision, and

it is recommended to choose the appropriate variable information board type and

setting distance according to the road conditions; When the distance between

the information board and the dynamic truck scale does not meet the driver's

visibility requirements due to the road alignment conditions, it is recommended

to limit the driving speed of the truck or adjust the angle of the information

board LED particles to improve the driver's visibility time.

3.3. Design of measures to reduce weighing errors

According to the requirements of overload division

in the penalty standard, in the case of running speed of 1~80km/h, the total

weight of the vehicle and cargo in the dynamic weighing should meet the

requirements of the accuracy level of 10, and the percentage of the agreed true

value of the total weight of the vehicle does not exceed the error of the first

inspection and subsequent inspection

± 5.00%, and the test error in use does not exceed ±10.0%.

In order to reduce the error

caused by pavement factors to weighing, the pavement in the area that affects

weighing before and after weighing equipment at direct enforcement stations

should meet the following requirements:

1) The longitudinal slope should

not be more than 2%, and the lateral slope of the pavement should not be more

than 2%;

2) when on the cement pavement, a

deformation joint, a tie rod and a filler are arranged between the backfill

cement concrete and the existing cement pavement;

3) When on the asphalt pavement, a gradient transition is adopted between

the backfill cement concrete and the existing asphalt surface course. Direction

enforcement station

selection points should avoid being installed on the

following road sections:

1) The road section within 200m from the level intersection;

2) the number of lanes changes in the road section;

3) overpass (aerodynamic influence) and approach bridge (poor uniformity)

sections;

4) sections of bridges or other structures that will have a dynamic impact

on vehicles;

5) Sections under or near radio transmission

stations and railway tracks under high-voltage power lines.

In addition, in order to reduce the weighing error caused

by the driving behavior of the vehicle, the following measures should be taken

in the weighing section:

1) When the driving lane is multi-lane, the roadway

dividing line adopts a solid line, and vehicles are prohibited from changing

lanes;

2) When the road section alignment is good and easy

to speed, set up the truck speed limit sign in front of the weighing detection

area;

3) In order to crack down on driving behaviors that

deliberately evade punishment such as blocking license plates, driving in the

wrong direction, and queuing and tailgating, illegal capture and identification

equipment can be added.

To sum up, the layout of direct enforcement

detection points should be comprehensively determined after comprehensively

considering the regional road network, road conditions and surrounding

environment, and the design of reducing errors should be carried out according

to the road conditions of the installation location to reduce the errors in the

operation and maintenance process. In order to reduce the cost of weigh-in-motion

construction, in addition to overall planning and reasonable selection of

layout points, it is also necessary to clarify the management authority,

coordinate the management from multiple departments and angles, and strive to

reduce overload behavior from the source.

Enviko Technology Co.,Ltd

Comments

Post a Comment